Collection and jetting apparatus addresses downhole debris and swarf removal that blocks access to completion hardware

Talk to an expertThe ClearBail™ bailer service is a versatile, dual-function device designed to clear blockages in downhole completion hardware, such as barrier isolation valves and nipple locks. The tool switches between powerful high-suction debris retrieval and high-pressure liquid jetting to remove viscous slurries, including grease, drilling mud, pipe dope, proppant, sand, scale, metallic swarf, and elastomer fragments. Engineered for precision and efficiency, the ClearBail service restores access to critical components that require mechanical shifting or pulling.

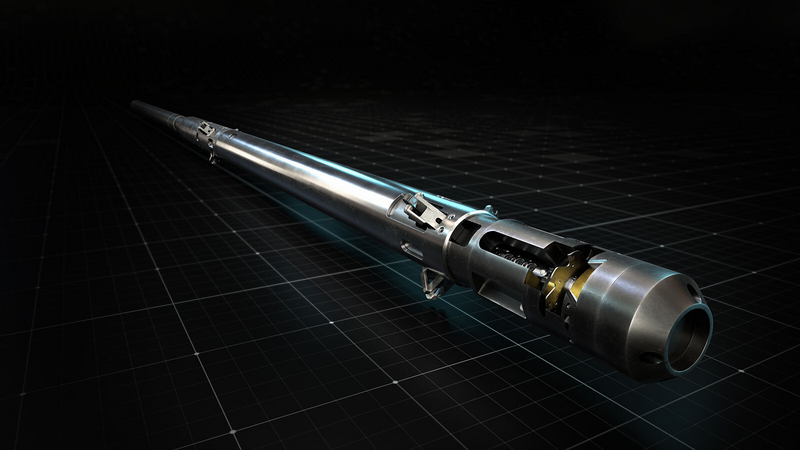

The apparatus is a high-performance downhole cleanup solution that combines a high-torque rotary unit with a high-displacement progressing cavity pump (PCP). ClearBall service generates up to 325 psi of suction pressure that ranges from 0.002-in. formation particles (e.g., sand) to metallic swarf and elastomer pieces up to 0.75 in. The versatile design of the PCP enables seamless switching from suction to high-pressure jetting to clear blockages. For light-duty cleanup applications, the device can be designed to output 15.5 US gal/min jetting through a slow-rotating washing nozzle to scour the pipe wall. Engineered for versatile downhole debris management, the ClearBail bailer service features three specialized collection chambers. The fine screen chamber captures particles from 0.03 to 0.05 in. to target fine formation rubble entrained in the wellbore. The medium chamber collects fragments from 0.05 to 0.25 in., including larger sand, proppant, scale, and metallic swarf. The large chamber filters debris from 0.25 to 0.75 in. and recovers larger metal fragments and elastomer pieces. Each 5-ft chamber is modular, and the system supports up to seven chambers (35 ft of debris collection per run). Customizable chamber configurations facilitate adaptability to diverse downhole applications. The ClearBail bailer service joins a dynamic electromechanical portfolio that unleashes innovative solutions for downhole challenges. This portfolio includes ClearTrac™ e-line tractors, ClearCut™ cutters (single blade, rotary blade, and slim 1 11/16-in.), ClearMill™ millers, and ClearShift™ high-expansion shifters.

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.