Remotely control and manage even the most complex reservoirs

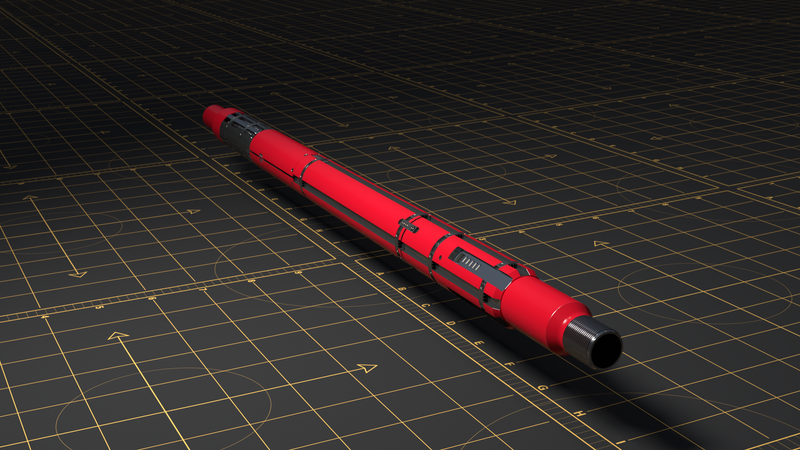

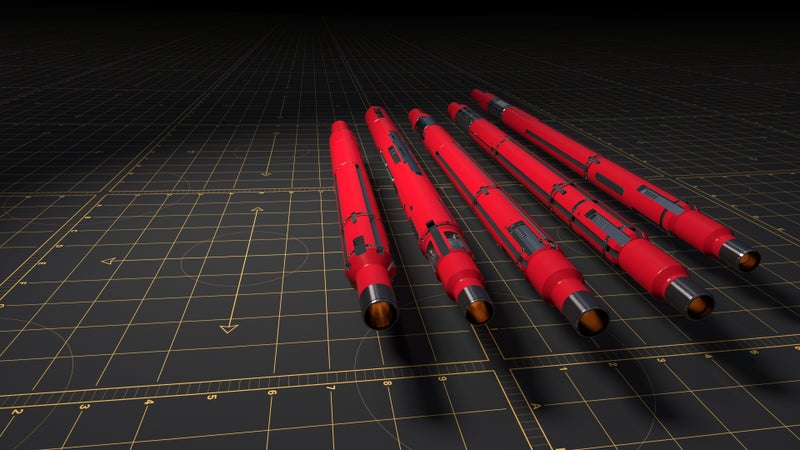

Talk to an expertHalliburton Intelligent Completion’s Digital Hydraulics™ multi-drop downhole control system that provides simple and reliable zonal control for even the most complex reservoirs. Digital Hydraulics system allows up to six flow control devices to be controlled from only three hydraulic control lines, making a large number of tubing hanger penetrations unnecessary and reducing the complexity of, and risk to, operations and logistics.

Digital Hydraulics system can control any flow control tool in the field-proven Halliburton Completion Tools inventory.

The Digital Hydraulics system is ideally suited for intelligent well applications with three to six zones that demand all-hydraulic control.

The Digital Hydraulics system can be used to control simple open/ close interval control valves (ICVs) or lubricator valves (LVs) to provide on/off flow control from each zone. When combined with the Accu-Pulse™ module and the HVC-ICV, the Digital Hydraulics system can provide variable flow control to multiple zones.

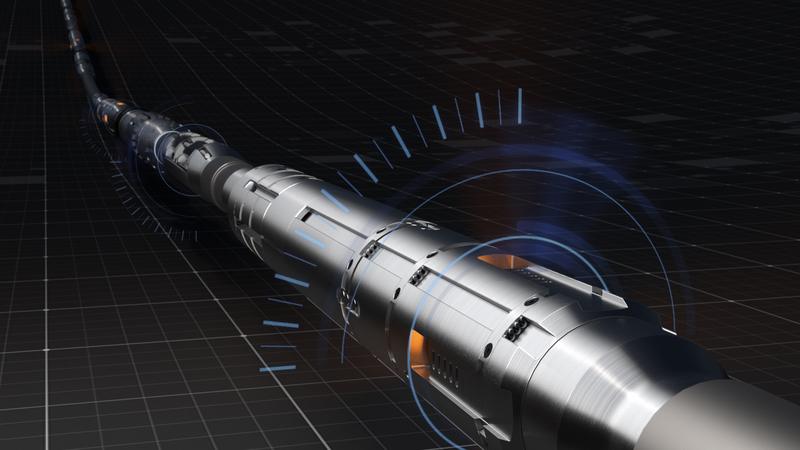

The Digital Hydraulics system is a patented design that uses the logical absence or presence of pressure (hydraulic code) to communicate between a surface controller and the downhole tools.

Existing pressure greater than 2,000 psi is represented by a “1” and pressure less than 500 psi is represented by a “0.” Depending on the sequence of 1s and 0s, communication to a particular flow control device is established with the Digital Hydraulics system.

Each flow control device is paired with a decoder that is designed to respond to its own unique code and to reject all other codes or sequences. Using this method, the communication between the surface controller and the downhole tools maintains its integrity – even when conditions such as temperature changes, long control lines, fluids and leaks can cause other hydraulic communication methods to fail.

A three-line Digital Hydraulics™ system is capable of independently controlling up to six control devices through the sequenced application of pressure on two of the three control lines.

The surface equipment for Digital Hydraulics system is designed as part of the Halliburton Digital Infrastructure supervisory application, SmartWell® Master system. A fully automated surface hydraulic system, controlled from a central location, allows control of the Digital Hydraulics system from a local or remote control station.

The SmartWell Master system translates the Digital Hydraulics system logic into standard central control room operations. This translation allows operators to easily monitor and control multiple completions, as well as an individual zone within an intelligent well completion.

The direct hydraulics downhole control system uses direct hydraulic control lines from the surface to remotely actuate downhole flow control devices.

The Accu-Pulse™ module enables incremental opening of a multi-position ICV to control produced or injected fluid rates for enhanced reservoir management.

The SmartPlex® downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore

The SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore.

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.