Magnetic ranging solutions provide collision avoidance, accurate well placement, and continuous drilling even in the most complex scenarios

Talk to an expertIn densely populated drilling fields, the risk of wellbore collisions increases. When this happens, damage to the wellbore can drastically increase costs and create safety hazards. Operators must precisely place wellbores for collision avoidance.

Halliburton’s magnetic ranging tools provide extreme precision and allow operators to place wellbores within a foot of each other for peak performance in applications like steam-assisted gravity drainage. Our active magnetic ranging system optimizes wellbore positioning when operators cannot access the target wellbore. This allows you to maintain a safe distance between wells, avoid potential collisions, and maximize resource recovery.

In oil recovery operations that require steam-assisted gravity drainage, operators must drill wells in close proximity to maximize resource recovery. Magnetic ranging solutions help operators guide the drilling of horizontal well pairs, which ensures optimal steam distribution and oil recovery.

Field days of relief well experience in the past decade

Blowout relief success rate

P&A intervention success

Continents where we operate

Intercepting a blowout well or drilling a relief well requires pinpoint accuracy to control the situation safely and efficiently. Halliburton’s active magnetic ranging system provides you with precise distance and directional data for well interception, regardless of your ability to access the target well. Because you have the exact parameters you need to hit your target, you can gain control of the situation successfully and safely.

Geothermal wells and advanced oil recovery techniques require precise well placement because of their complex environments. With Halliburton’s solutions, including rotary magnet ranging systems, operators can gather real-time data without sending tools down the well. This reduces the likelihood of tool damage and subsequent costly, time-consuming retrievals in the wellbore.

When operators want to maximize their oilfield investments and drill new wells in mature fields, they need to steer clear of existing infrastructure. Otherwise, they could damage nearby wells as they conduct infill drilling operations. Passive ranging solutions detect magnetic fields from existing casings. This helps you guide well placement through crowded fields safely and effectively.

Avoid costly drilling delays caused by frequent surveys or inaccurate well placement. Halliburton provides ranging solutions that eliminate the need for wireline interventions and help you keep your drilling operations on track. We help you reduce rig time and lower operational costs while you maintain the utmost precision, even in difficult environments.

With Halliburton’s comprehensive suite of magnetic ranging solutions, operators can overcome the most complex drilling challenges with precision and confidence. From collision avoidance to precise well placement in advanced oil recovery applications, our technologies ensure safer, more efficient operations. We help you reduce costs, improve asset value, and succeed in the most demanding environments

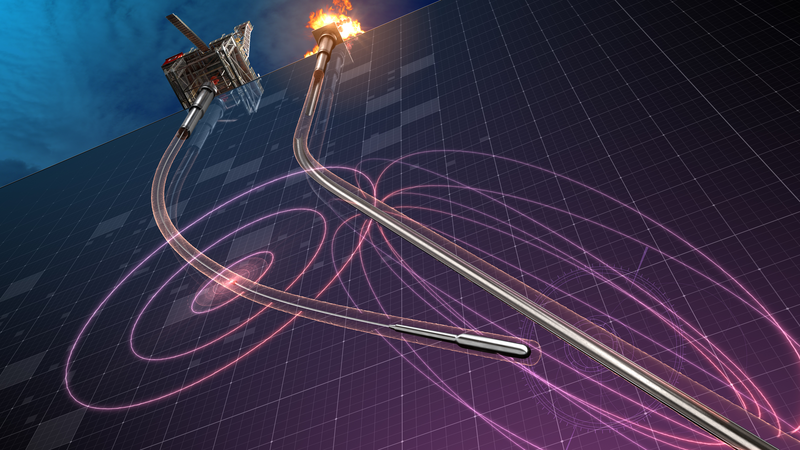

The Aurora™ surface-access magnetic ranging service provides accurate well placement in SAGD applications without downhole intervention.

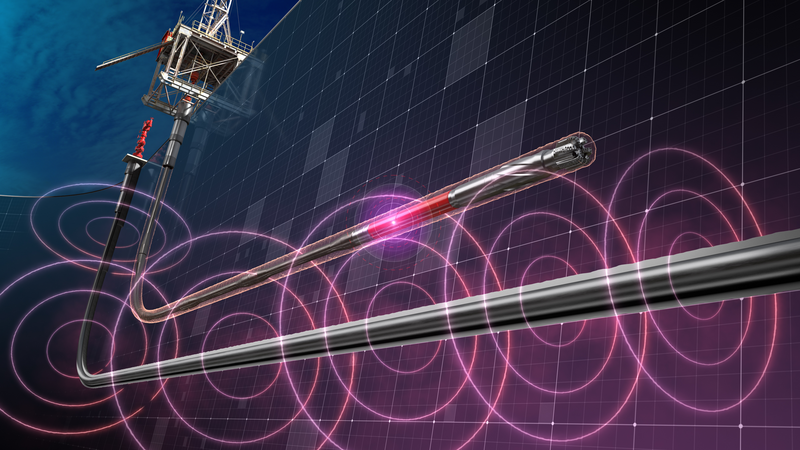

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.

The Passive Magnetic Ranging (PMR) service utilizes the remnant magnetic fields on target well tubulars to provide a distance and direction between wellbores.

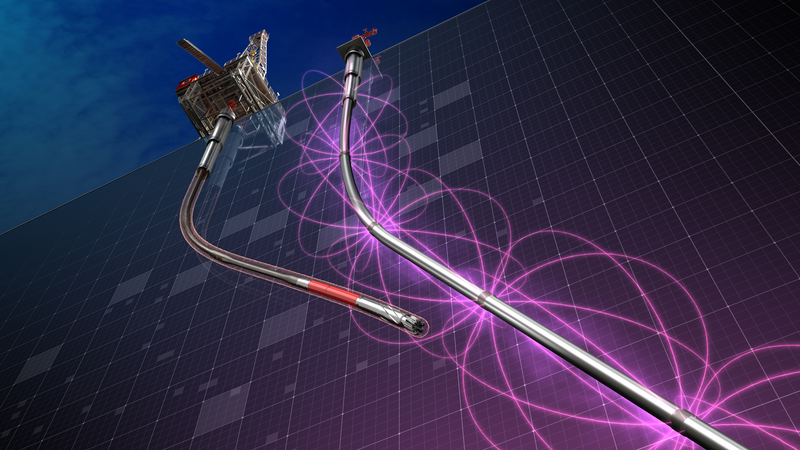

The MGT™ magnetic guidance tool is an active magnetic ranging solution that allows parallel wells to be drilled within highly accurate separation tolerances.

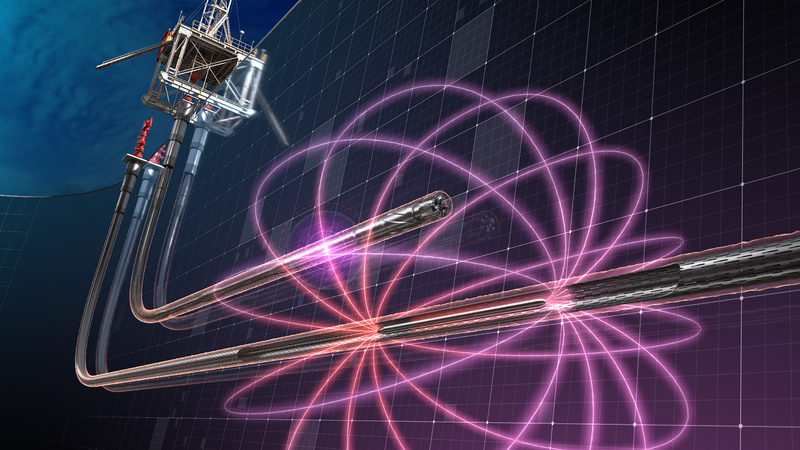

The RMRS™ rotary magnet ranging system provides active magnetic ranging to accurately determine the position of nearby wellbores and reduce survey errors.