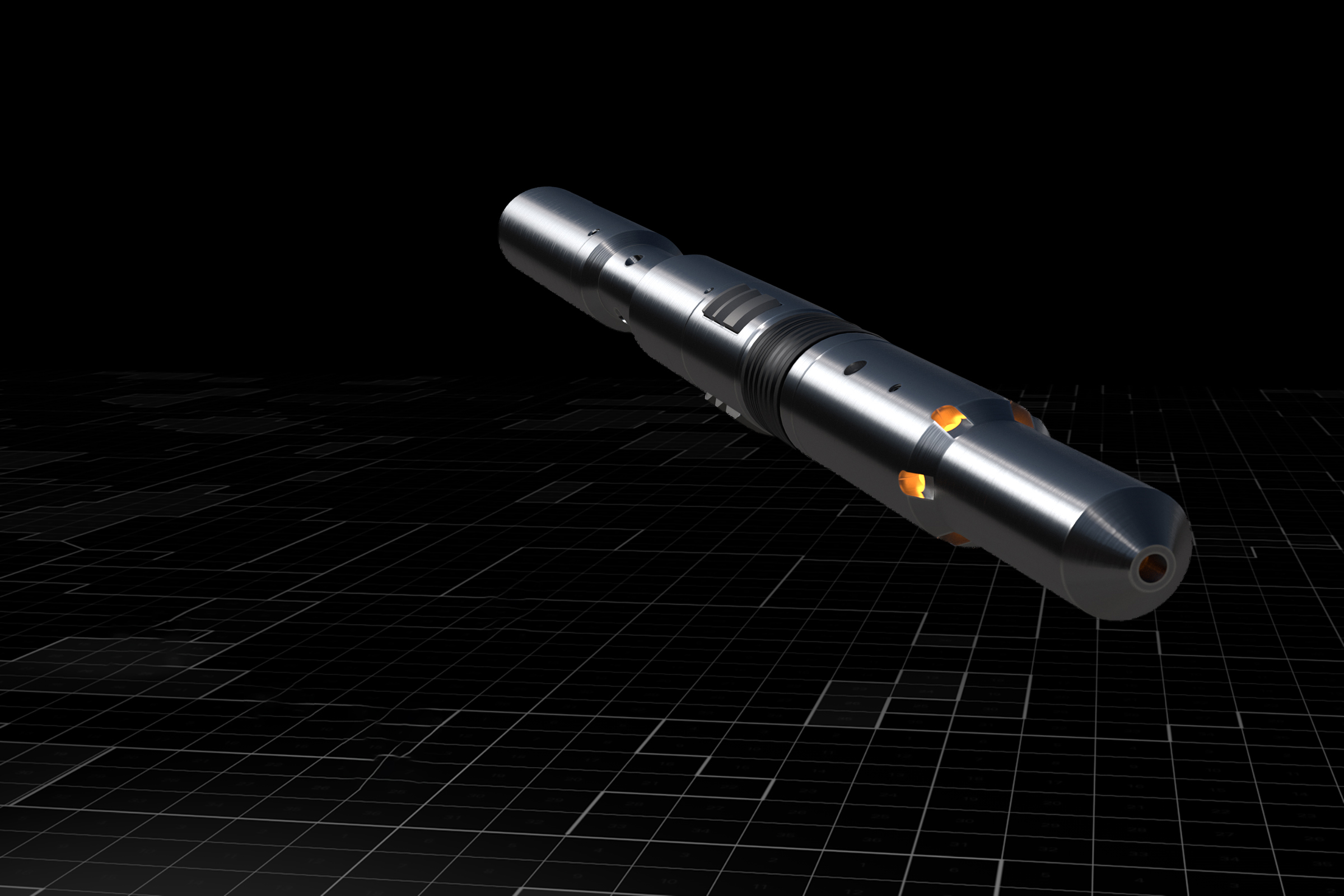

V0-qualified, high-pressure plugs designed for use in extreme temperature and pressure environments

Talk to an expert| Tubing size | Nipple profile | Nipple profile and lock mandrel |

|---|---|---|

| Seal bore | API 14L validation | |

| 3 1/2 | 2.250 | V2 |

| 2.313 | V2 | |

| 2.375 | V2 | |

| 2.562 | V2 | |

| 4 1/2 | 3.125 | V2 |

| 3.250 | V2 | |

| 3.375 | V2 | |

| 3.500 | V2 | |

| 5 1/2 | 4.063 | V2 |

| 4.188 | V2 |

| Tubing size | Nipple profile | |

|---|---|---|

| Seal bore | API 14L validation | |

| 3 1/2 | 2.250 | V1 |

| 2.313 | V1 | |

| 2.375 | V1 | |

| 2.437 | V1 | |

| 2.562 | V1 | |

| 4 1/2 | 3.125 | V1 |

| 5 1/2 | 4.313 | V1 |

| 4.688 | V1 | |

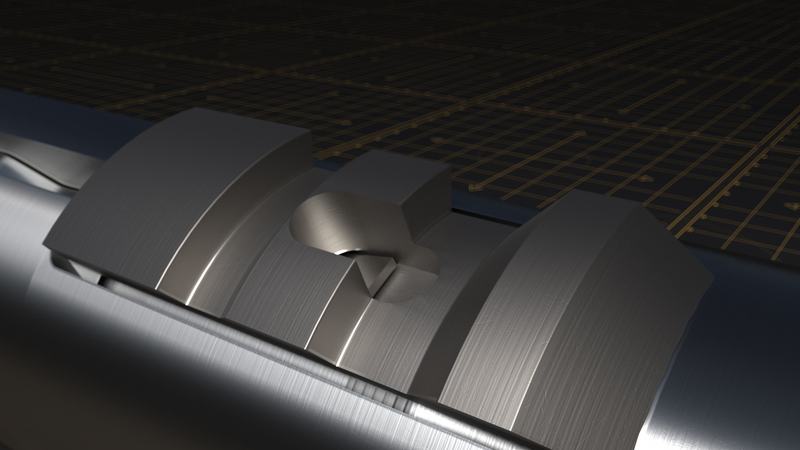

No-go landing nipples designed for use in standard and heavyweight tubing.

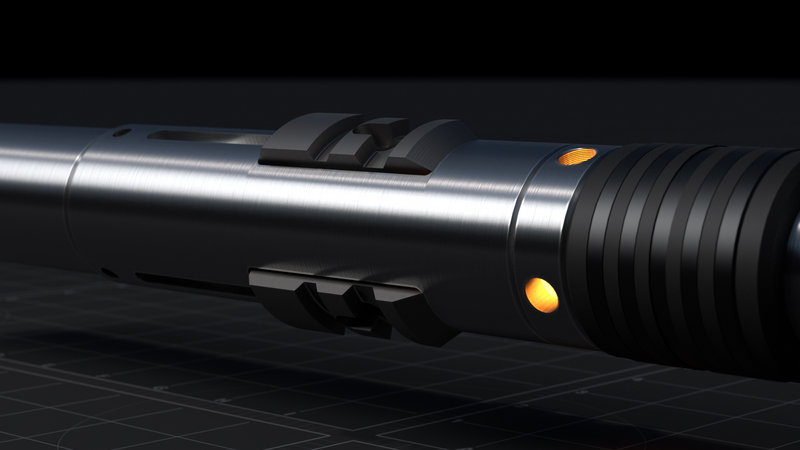

Selective by running tool industry-standard flow controls.

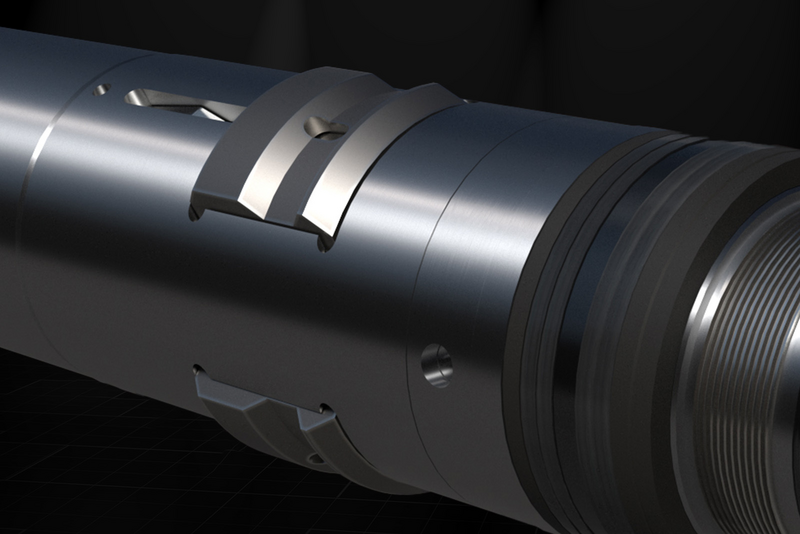

Landing nipple and lock mandrel systems well-suited for high-pressure, high-volume large bore completions.

The SRP plug system is designed primarily for use in horizontal subsea trees.